![]()

🧩 Connecting the Dots: Clause 7.2 “Samples” ↔ Technical Standards & Building Codes

Imagine every standard, test method and building code as the recipe book for your project.

Clause 5.4 “Technical Standards and Regulations” says the Works must be baked exactly to that recipe—using the country’s technical standards, building, construction and environmental laws, and other standards specified in the Employer’s Requirements.

Clause 5.4 “Technical Standards and Regulations” says the Works must be baked exactly to that recipe—using the country’s technical standards, building, construction and environmental laws, and other standards specified in the Employer’s Requirements.

🧁

But how does the Engineer taste-test the cake before it’s baked at full scale? That’s where Clause 7.2 steps in: The Contractor must deliver labelled, representative samples (and any extra ones “instructed by the Engineer as a Variation”). Those swatches, cubes and mock-ups are the bridge between the paper rules in 5.4 and the physical reality on site.

⟶

📦 Samples (7.2)

Contractor submits labelled, code-tagged samples via the 5.2 pipeline

(21-day “deemed consent” in 2017 Book)

⟶

⟶

(21-day “deemed consent” in 2017 Book)

🛠️ Variations (13)

Extra samples? Engineer’s order is a Variation (Clause 13). Contractor gets time/cost adjustment.

⟶

🚫 Rejection (7.5)

Bulk deliveries drifting from approved samples can be rejected—no arguments, the swatch settles it.

| Code Family | Typical 7.2 Sample | Compliance Check (Engineer’s Lens) |

|---|---|---|

| Concrete – ASTM C39 / ACI 318 | 150 mm cube set + mix sheet | ≥ design f’c; certified lab stamp |

| Rebar – BS 4449 / EN 10080 | 1 m bar with heat-number tag | Yield, elongation, rib geometry |

| Structural steel – EN 10025 | Mill coupon + 3.1 cert | Charpy at -20°C; grade S355 |

| Welds – AWS D1.1 | Macro-etched weld coupon | Fusion line, throat size, defects |

| Fire stopping – IBC §714 / UL-1479 | Intumescent seal mock-up | 2 h rating on through-wall test |

| HVAC ducting – SMACNA | 300 mm duct section | Gauge, seam type, leakage class |

| Paint & coatings – ISO 12944 | Coated plate (50 µm dft) | Dry-film thickness, gloss, salt-spray |

| Low-VOC finishes – LEED v4 | 250 ml paint can + SDS | VOC ≤ 50 g/L; ecolabel proof |

| Cable – IEC 60364 | 1 m LV cable | CPR fire class, conductor size |

| Timber – FSC / EN 14080 | 300 mm glulam block | FSC chain-of-custody; moisture 12% |

Each sample must arrive “labelled as to origin and intended use”—a deceptively powerful line in both books that shuts down mix-ups later.

🧵 The “Paper-to-Site” Clause-Chain — How a Dry Standard Becomes Concrete Reality

Grab your site boots and a coffee ☕—we’re walking the life-cycle of a code requirement through the FIDIC Yellow Book, one clause at a time. Each step is a link in a compliance chain; break the link and quality, time ⏱️ or money 💸 are at risk.

📚

Link 1: 5.4 Technical Standards

Where the rules live.

⟶

This is the bookshelf: Eurocodes, ASTM specs, laws, Employer’s special rules.

Both editions: Design and finished Works “shall comply with the Country’s technical standards, building, construction and environmental Laws… and other standards specified in the Employer’s Requirements.”

More on Clause 5.4

Both editions: Design and finished Works “shall comply with the Country’s technical standards, building, construction and environmental Laws… and other standards specified in the Employer’s Requirements.”

More on Clause 5.4

📑

Link 2: 5.2 Contractor’s Docs

Turning rules into drawings & data sheets.

⟶

Before steel is cut, the Contractor’s calcs, BIM, mix designs, and certificates run the “Review/No-Objection” conveyor belt.

2017: Engineer gets 21 days; silence = deemed “No-objection.”

Think: airport security for documents.

More on Clause 5.2

2017: Engineer gets 21 days; silence = deemed “No-objection.”

Think: airport security for documents.

More on Clause 5.2

🎨

Link 3: 7.2 Samples

Paper meets physical world.

⟶

Swatches, rebar coupons, or mock-ups arrive—clearly labelled.

Engineer consents or not. Extra samples? They’re a Variation.

The sample is the contract’s DNA strand.

More on Clause 7.2

Engineer consents or not. Extra samples? They’re a Variation.

The sample is the contract’s DNA strand.

More on Clause 7.2

👁️

Link 4: 7.3 Inspection

The on-site eyesight test.

⟶

Employer’s team can inspect any time. Contractor must allow access.

“Show me” moment—no surprises buried behind drywall.

More on Clause 7.3

“Show me” moment—no surprises buried behind drywall.

More on Clause 7.3

🧪

Link 5: 7.4 Testing

Lab goggles on!

⟶

Contractor runs all tests, Engineer can vary test details.

Employer-caused? Contractor claims EOT/cost.

More on Clause 7.4

Employer-caused? Contractor claims EOT/cost.

More on Clause 7.4

❌

Link 6: 7.5 Defects & Rejection

Pass ✅ or fail ❌.

⟶

Failed items must be fixed or are rejected—costs can be deducted.

Project’s quality bouncer: “Not on the guest list? You’re out.”

Project’s quality bouncer: “Not on the guest list? You’re out.”

💸

Link 7: 13 Variations

Money & time catch-up.

⟶

New standards or extra samples/tests? These become Variations—triggering price/time adjustment.

More on Clause 13

More on Clause 13

📝

Link 8: 20 Claims & EOT

The formal scoreboard.

⟶

Any delay/cost from above? Contractor files a claim within 20 days.

Paperwork = open chequebook.

More on Clause 20

Paperwork = open chequebook.

More on Clause 20

🎓

Link 9: 9 Tests on Completion

The end-of-season finale!

The Works face final trials. Fails return to 7.5; passes unlock Taking-Over.

The exam where every earlier link proves its worth.

More on Clause 9

The exam where every earlier link proves its worth.

More on Clause 9

Why This Chain Matters:

Miss Link 2? You build off an unapproved drawing—costly rework.

Skip Link 3? No quality baseline—arguments explode.

Ignore Link 6? Sub-par materials slip through—defects, claims, drama.

Keeping the chain tight means audit-ready evidence, fewer disputes, smoother cash flow, and a project that actually meets the law—not just the tender spec.

Miss Link 2? You build off an unapproved drawing—costly rework.

Skip Link 3? No quality baseline—arguments explode.

Ignore Link 6? Sub-par materials slip through—defects, claims, drama.

Keeping the chain tight means audit-ready evidence, fewer disputes, smoother cash flow, and a project that actually meets the law—not just the tender spec.

🔑 Key Interpretations & Implications — The “What Does It Really Mean?” Edition

Grab a coffee and let’s unpack the fine print behind Clause 7.2 “Samples.” ☕✨

This is the backstage tour that explains why those tiny material swatches can move millions of dollars and weeks on the programme.

This is the backstage tour that explains why those tiny material swatches can move millions of dollars and weeks on the programme.

Both editions say the Engineer may ask for “additional samples.”

1999 hints these are Variations (“instructed by the Engineer as a Variation”).

2017 shouts it—on its own line and cross-linked to Clause 13.

Practical upshot: As soon as the Engineer requests more, the Contractor’s claim clock starts. Smart contractors file a 20-day claim notice (Clause 20) the same day!

1999 hints these are Variations (“instructed by the Engineer as a Variation”).

2017 shouts it—on its own line and cross-linked to Clause 13.

Practical upshot: As soon as the Engineer requests more, the Contractor’s claim clock starts. Smart contractors file a 20-day claim notice (Clause 20) the same day!

2017: Every sample runs through the Clause 5.2 review pipeline — 21-day deemed consent. If the Engineer stays silent, sample is “approved by silence.”

1999: Leaves timing vague (“reasonable time”).

Why it matters: Predictable turnaround is gold for procurement. Under 2017, silence = approval.

1999: Leaves timing vague (“reasonable time”).

Why it matters: Predictable turnaround is gold for procurement. Under 2017, silence = approval.

| Risk | Default Holder | Escape Valve |

|---|---|---|

| Producing contract-required samples | Contractor (already priced) | None |

| Engineer’s extra “just-curious” samples | Employer via Variation | N/A |

| Delay from late sample approval | Employer/Engineer → Contractor entitled to EOT & Cost under 8.5/8.4 + 20 | Keep meticulous records! |

Each sample must be “labelled as to origin and intended use.” This is a powerful forensic tool. When the delivered materials differ, the Engineer simply says, “Match this or replace.”

No long arguments about RAL codes—just visual truth.

No long arguments about RAL codes—just visual truth.

A slipped approval on a critical-path sample can ripple through manufacturing, shipping, and crane time.

2017: Links to 5.2 clock for clear Extension of Time.

1999: Must prove the Engineer was unreasonable—often a time drain.

2017: Links to 5.2 clock for clear Extension of Time.

1999: Must prove the Engineer was unreasonable—often a time drain.

Approved samples are Exhibit A in disputes—anchor for 7.5 Rejection or 11.2 Cost of Remedying Defects.

Store them securely—ideally in a locked sample library, plus hi-res cloud photos!

Store them securely—ideally in a locked sample library, plus hi-res cloud photos!

Many contracts now allow digital samples—textures in BIM or 4K scans.

Tip: Amend Clause 7.2 in your Particular Conditions to accept approved BIM/digital samples (e.g., IFC or .rvt files) as fully valid.

Tip: Amend Clause 7.2 in your Particular Conditions to accept approved BIM/digital samples (e.g., IFC or .rvt files) as fully valid.

- Front-load the schedule with a “sample tracker” tied to procurement Gantt.

- Bundle claims: if extra samples hit lead times, claim Variation + EOT in the same notice.

- Label smart: QR code tags linking to an online sample database. One scan ends debates.

- Educate the site team: No installation until the sample is fully approved and logged!

For maximum claims protection, treat samples as both a risk and an opportunity: log approvals, take timestamped photos, and build a “sample library” your future self (and your lawyer) will thank you for!

🛠️ Super-Charging Your Particular Conditions for Clause 7.2 “Samples”

Ready to turn the “little-swatches” clause into a crystal-clear, dispute-proof powerhouse? Grab your hard hat and let’s workshop practical tweaks you can bolt into the Particular Conditions—while staying true to the FIDIC Golden Principles. 🏗️✨

1️⃣

⏱️Lock-in a Rock-Solid Approval Clock

Set a 14 or 21-day clock. Add deemed-consent: “No reply = consent.”

It syncs procurement with programme dates and stops scope-creep delays—no more “waiting forever” for approval.

2️⃣

📅Build a “Samples Schedule” Into the Programme

List every required sample, submission deadline, lead-time buffer, and critical path impact.

Treats sample approval as a true milestone, not an afterthought—less chance for late shocks.

3️⃣

🔍Define Exactly What Counts as a Sample

Micro-definitions: swatch, mock-up, panel, digital texture, etc. Set size/format rules.

Removes “is this a sample?” arguments—everyone knows what’s expected.

4️⃣

💻Embrace Digital: BIM & Hi-Res “E-Samples”

Allow IFC/Revit files or 4K scans first, physical if needed. Label digital samples with BIM hash codes.

Slashes shipping time and carbon. One-click matching between model and reality.

5️⃣

🏷️QR-Code Traceability & Site “Sample Library”

QR-codes link to online approvals/photos. Lockable site box for physical samples.

Instant traceability kills most disputes. Library box keeps critical swatches safe, clean and accessible.

6️⃣

💸Extra Samples = Automatic Clause 13 Variation

Explicit: “Engineer-requested sample not in ER = Variation + cost + EOT + mark-up.”

Removes haggling, sets expectations up front—costs and time get tracked automatically.

7️⃣

📦Storage, Return & Disposal Rules

State who pays, where samples go after—returned, archived, recycled?

No wrangling over storage costs or “who keeps the samples” at project end.

8️⃣

🌱Sustainability & ESG Filters

Require an EPD or circular-economy scorecard with each sample.

Boosts green credentials and makes approval conditional on sustainability—not just looks.

9️⃣

⚠️Safety & Handling Mini-Clause

Cross-link to Clause 4.8: require data sheets and PPE for any hazardous sample.

Prevents site injuries and regulatory headaches during sample handling.

🔟

📂Dispute-Ready Documentation

Mandate a jointly signed Sample Approval Register + QR log; state it’s “conclusive evidence.”

No more “he-said-she-said” arguments—signed logs are gold in claims and disputes.

1️⃣1️⃣

🚦Early-Warning Triggers

Contractor must flag if sample approval is drifting toward critical path (e.g., 7 days pre-impact).

Gives the Engineer time to speed up reviews—keeps the programme on track and avoids surprises.

Pro Tip: The best Particular Conditions aren’t just “lawyer-proof”—they’re site-ready. Workshop these tweaks with your whole delivery team for a clause that works in the real world, not just on paper!

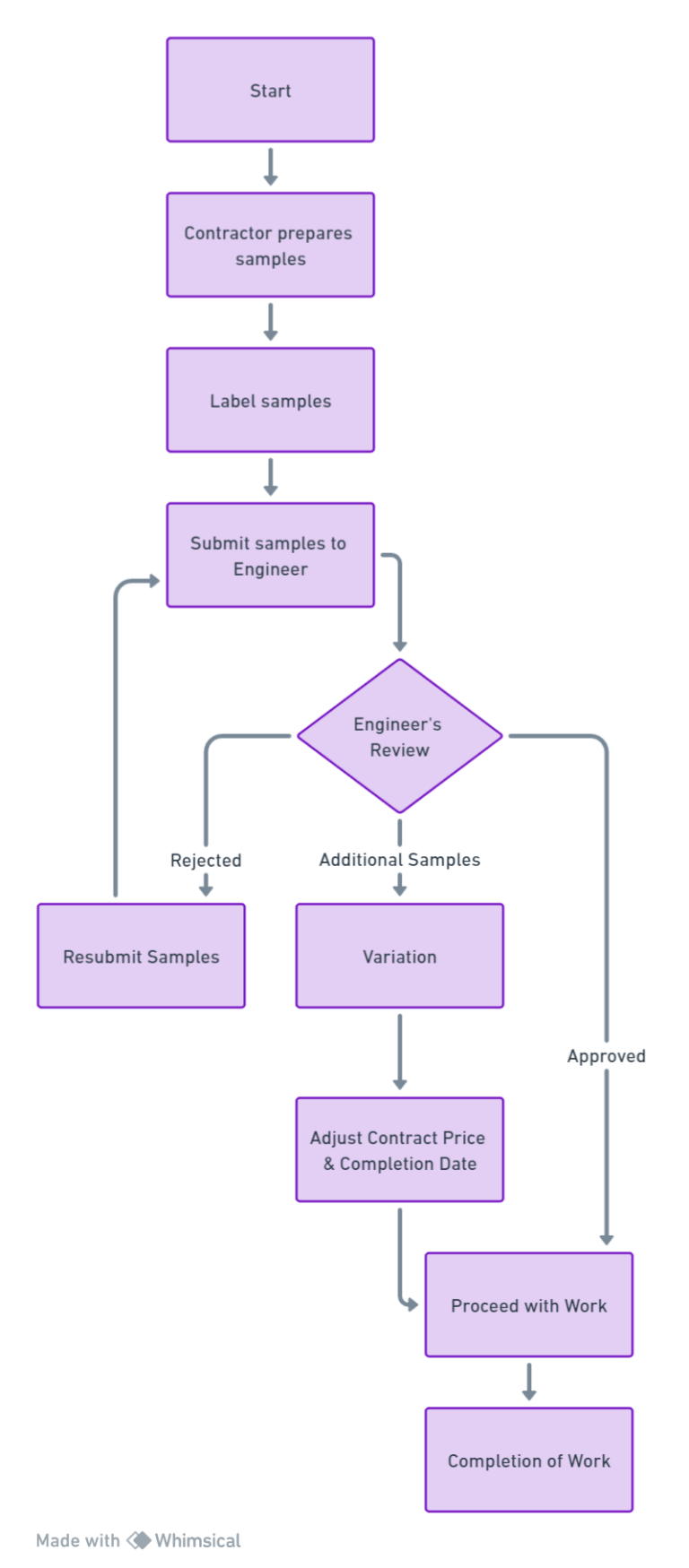

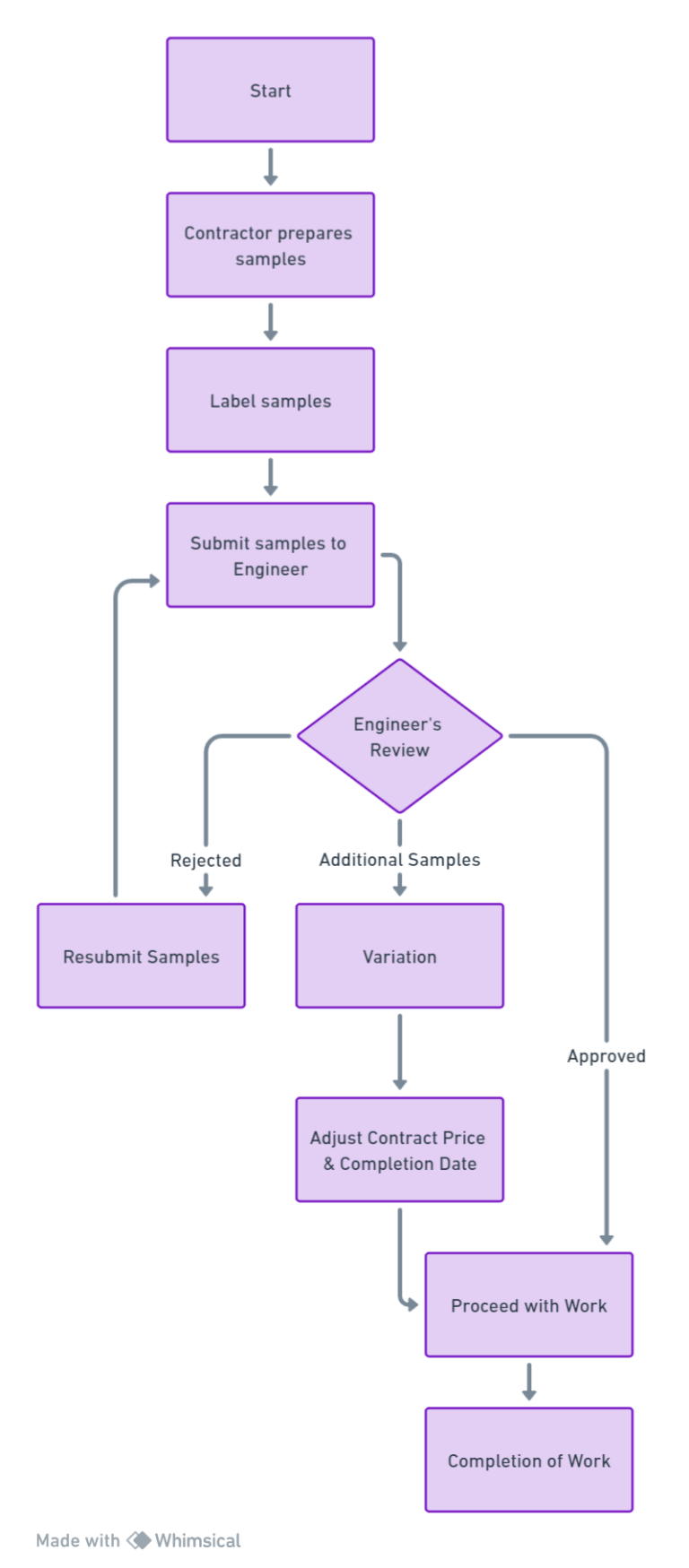

🔄 Sample Approval Flowchart: From Contract to Completion

🔗 View Full-Size Flowchart

Visual: The journey of a sample through review, approval, resubmission, and variation in FIDIC Clause 7.2

1

🚦Start

Project begins; contract requires samples for certain materials or workmanship.

2

🛠️Contractor Prepares Samples

Contractor readies required samples per contract specs and Employer’s Requirements.

3

🏷️Label Samples

Each sample must be labeled with its origin and intended use (Clause 7.2).

4

📤Submit Samples to Engineer

Labeled samples go to the Engineer for review and approval.

5

🔎Engineer’s Review

Decision node:

- Approved: Proceed with Work.

- Rejected: Contractor must resubmit improved sample.

- Additional Samples: If Engineer wants more, triggers a Variation.

6

✅Proceed with Work

With approval, Contractor proceeds per programme and specs.

7

🔄Resubmit Samples (if Rejected)

Rejected samples must be improved and resubmitted—loop continues until approval.

8

💸Variation: Additional Samples

Engineer-requested extra samples are a Variation—Contractor is entitled to cost/time adjustment.

9

📝Adjust Contract Price & Completion Date

Variation may require revising the contract price or extending the completion date.

10

🏁Completion of Work

Work is completed after all samples are approved and any variations are resolved.

🔍 Clause 7.2 “Samples” – Practical Checklists

Ready-to-use checklists for project kick-off packs or quality plans.

Tick ✔️ each task as you go for true “audit-readiness.”

Tick ✔️ each task as you go for true “audit-readiness.”

| # | Task | Who owns it? | Source / Ref. | ✅ |

|---|---|---|---|---|

| 1 | Extract every sample expressly required in the Employer’s Requirements (ERs) | Contractor QS / QA | ERs + Clause 7.2 (a) | |

| 2 | List additional samples implied by codes via Clause 5.4 (e.g., fire-test panels) | Contractor Design Lead | Codes register | |

| 3 | Schedule production lead times in the 8.3 Programme | Planner | Prog. rev. A | |

| 4 | Physically prepare samples to match final‐production process (no lab “specials”) | Trade Sub-contractor | ITP-001 | |

| 5 | Label each sample with origin, intended use, code reference & QR link to certs | Site QA | Labelling SOP | |

| 6 | Photograph each sample for the digital log before submission | Doc‐Control | DC-Checklist |

| # | Task | Who owns it? | Source / Ref. | ✅ |

|---|---|---|---|---|

| 1 | Compile transmittal pack: sample, test certs, SDS, BIM material file (if used) | Doc-Control | Transmittal TMP-07 | |

| 2 | Submit via Clause 5.2 workflow; start the 21-day stopwatch (2017) / agreed days (PCs) | Contractor | CDR Portal | |

| 3 | Log submission & due date in the “Sample Tracker” register | Planning Eng. | Tracker v2 | |

| 4 | Engineer acknowledges receipt within 2 working days | Engineer | Inbox ack. | |

| 5 | Engineer issues Consent / Comments / Rejection within review window | Engineer | Review form | |

| 6 | If silent on day 21, deem consent (per 5.2) and notify Employer | Contractor | NCR-DC-02 |

| # | Task | Who owns it? | Source / Ref. | ✅ |

|---|---|---|---|---|

| 1 | Record any Engineer request for extra samples as a potential Variation | Project Manager | Clause 7.2 (b) | |

| 2 | Issue 20-day notice under Clause 20 for cost/time impact | Contractor | Claim N-07 | |

| 3 | Agree Variation scope & valuation under Clause 13 | QS + Engineer | VO-File | |

| 4 | Update programme & cash-flow forecasts to include the Variation | Planner | Rev. B |

| # | Task | Who owns it? | Source / Ref. | ✅ |

|---|---|---|---|---|

| 1 | Store approved samples in a lockable, climate-controlled “Sample Library” | Site QA | QP §7.2.4 | |

| 2 | Scan QR-code on receipt into the digital register; link to consent letter | Site QA | Register v3 | |

| 3 | Restrict installation to materials that match an approved sample & label | Foreman | Toolbox Talk | |

| 4 | During 7.3 inspections, cross-check bulk deliveries against library sample | Engineer Rep. | ITP-Stage 2 | |

| 5 | Archive superseded samples when standards change (red “Obsolete” tag) | Doc-Control | Archive log | |

| 6 | Hand over final sample catalogue to Employer at Take-Over (for FM reference) | Contractor | Handover Index |

Keep this checklist live! Audit-ready, traceable samples = fewer disputes and faster handover.

📝 Clause 7.2 “Samples” — Ready-to-Copy Letter Templates

Six fill-in-the-blanks letters for every scenario under Clause 7.2.

Replace grey ‹…› fields with project specifics. Print on letterhead.

Replace grey ‹…› fields with project specifics. Print on letterhead.

[Contractor’s Letterhead]

Ref.: ‹CTR-L-07.2-001› Date: ‹DD MMM YYYY›

To: The Engineer

‹Engineer’s Company›

‹Address›

Subject: Submission of Samples in Accordance with Clause 7.2(a)

Dear Sir/Madam,

In compliance with **Clause 7.2(a)** and the sample schedule appended to our

Programme (rev. ‹…›), we hereby submit:

▪ Sample No.: ‹S-CUR-001› – Curtain-wall aluminium extrusion

▪ Intended Use: Curtain-wall mullions – Levels 3–10

▪ Origin: ‹Supplier›, Batch ‹…›

▪ Associated Standard: EN 755-9 (per **Clause 5.4**)

▪ Enclosures: Test certificate, SDS, BIM material file (RVT), photo log

The samples are labelled as required and are available for physical

inspection in the site “Sample Library.”

Kindly issue your **Consent / Comments / Disapproval** within the review

period specified in **Sub-Clause 5.2** (21 days closing ‹DD MMM YYYY›).

Yours faithfully,

‹Name›

Project Manager – ‹Contractor›

[Engineer’s Letterhead]

Ref.: ‹ENG-L-07.2-VAR-002› Date: ‹DD MMM YYYY›

To: ‹Contractor›

‹Address›

Subject: Instruction for Additional Samples (Clause 7.2(b)) – Proposed Variation

Dear Sirs,

During the mock-up review on ‹DD MMM YYYY› we noted colour variance in

the façade panels. Pursuant to **Clause 7.2(b)**, you are hereby instructed

to provide three additional full-height panels (1 m × 3 m) for daylight

assessment.

As these samples are **not included** in the Employer’s Requirements,

this instruction shall constitute a **Variation under Clause 13**. Please

submit your proposal for any adjustment to the Contract Price and Time

within 14 days.

Regards,

‹Name›

The Engineer

[Contractor’s Letterhead] Ref.: ‹CTR-N-20-007› Date: ‹DD MMM YYYY› To: The Engineer Subject: Notice under Sub-Clause 20.2 – Delay from Late Consent of Samples Dear Sir/Madam, We refer to Sample Package SP-04 (fire-rated doors) submitted on ‹DD MMM YYYY›. The review period under **Sub-Clause 5.2** expired on ‹DD MMM YYYY› without a consent or comment. This has delayed procurement of long-lead doors by ‹…› days, impacting the critical path activity “Close building envelope.” In accordance with **Sub-Clause 20.2**, we hereby give notice of our intention to claim an **EOT and associated Costs**. A fully detailed claim will follow within 28 days. Yours faithfully, ‹Name› Contracts Manager

[Contractor’s Letterhead] Ref.: ‹CTR-CL-07.2-012› Date: ‹DD MMM YYYY› To: The Engineer Subject: Detailed Claim – Additional Stone Cladding Samples (Variation VO-04) Dear Sir/Madam, Further to your Instruction ENG-L-07.2-VAR-002, please find our claim summary: | Item | Qty | Cost (USD) | |------|-----|------------| | Quarry extraction & cutting | 3 panels | 4,200 | | Air freight (3 × 150 kg) | — | 1,950 | | Sample stand fabrication | — | 620 | | Subtotal | | 6,770 | | O/H & Profit (10 %) | | 677 | | **Total** | | **7,447** | Time impact: 7 calendar days (see attached programme fragnet). We request you to issue a Variation Order under **Clause 13.3** adjusting both Contract Price and Time accordingly. Kind regards, ‹Name› Quantity Surveyor

[Contractor’s Letterhead] Ref.: ‹CTR-L-07.2-CE-015› Date: ‹DD MMM YYYY› To: The Engineer Subject: Deemed Consent of Samples – Sub-Clause 5.2(e) Dear Sir/Madam, Reference is made to Transmittal T-07.2-11 for glass samples submitted on ‹DD MMM YYYY›. The 21-day review period lapsed on ‹DD MMM YYYY› with no response. As provided by **Sub-Clause 5.2(e)**, the samples are deemed to have received your Consent. We will proceed with bulk procurement in reliance on this deemed consent unless advised otherwise within 3 days. Sincerely, ‹Name› Procurement Lead

[Contractor’s Letterhead] Ref.: ‹CTR-L-07.2-RS-021› Date: ‹DD MMM YYYY› To: The Engineer Subject: Resubmission of Modified Sample – Response to Rejection R-07.2-05 Dear Sir/Madam, Following your rejection dated ‹DD MMM YYYY› citing non-conformity with ISO 12944 corrosion protection category C5-M, we have re-coated the steel plate to 320 µm DFT and attached an updated laboratory salt-spray certificate. Please find the revised sample (S-STE-014-B) labelled and logged in the Sample Library. We trust this addresses your concerns and request your review at your earliest convenience. Regards, ‹Name› Site QA Engineer